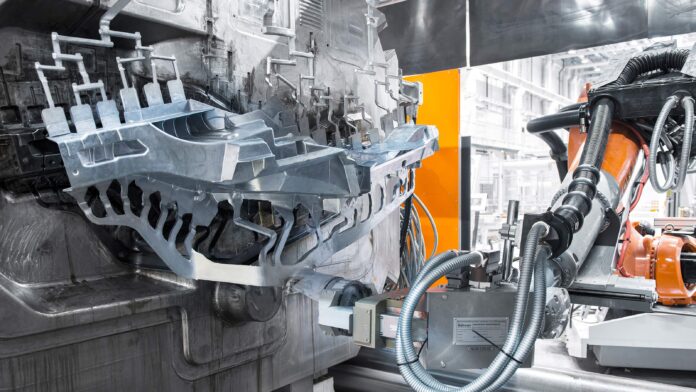

Die-casting refers to pouring molten metal into a mold under high pressure. It is a manufacturing process used to create complex metal parts using reusable molds called dies. The entire process uses four basic components, the die-casting machine, a furnace, dies, and metal.

Different projects require different die casting processes. Therefore, it is necessary to know the positives and negatives of each die-casting method. This article revolves around a detailed overview of the most common die-casting processes and their pros and cons.

Die-Casting Processes

The Hot-Chamber Die-Casting

The most common die-casting method is the hot-chamber die-casting. Sometimes also called gooseneck or hot casting. The process gets its name from the arrangement of the components.

A chamber is placed on top of a furnace which provides continuous heat to keep the metal molten. An injector applies high pressure to the metal such that it travels up the gooseneck and into the die cavity.

The mold or the die is attached at the end of the gooseneck. There are two parts of the die, fixed and moveable. Once the molten metal reaches the fixed die, it is left for solidification. When it solidifies, the moveable die is removed and the product is ejected.

It is important to know that hot chamber casting is only suitable for metal alloys having low melting points like magnesium, copper, zinc, etc.

Pros

- More production rate

- Minimal wastage

- Durable castings

- Inexpensive manufacturing

- Additional melting equipment is not needed

Cons

- Heating issues

- High pressure needed for casting

- Cost-effective for bulk casting only

Cold Chamber Casting Process

As the name indicates, the cold chamber die-casting doesn’t require the metal in molten form. Here, the molten metal is poured into the casting chamber automatically or manually. This casting chamber connects to the die cavity that further joins to an ejector pin.

When the metal is in the casting chamber, a high-pressured plunger presses to travel to the mold. Once the fixed part of the die cavity is filled with motel metal, it is left for solidifying without removing the pressure.

Note that the cold chamber casting is suitable for metals with high boiling points like aluminum and brass.

Pros

- Simpler process

- Low running cost of the machine

- Dimensionally accurate castings

- Heavy-duty manufacturing

- Denser castings

Cons

- Not much resistant castings

- Vulnerable to oxidations and other reactions

- Comparatively slow process

Other Kinds of Die-Casting Processes

High-Pressure Die-Casting:

In high-pressure die-casting, the molten metal is forced into the mold horizontally using high pressure. The strong press remains until the metal solidifies. This process is known for its premium surface finish and optimal mechanical properties of the product.

The high-pressure casting method bests the low-pressure casting method for its shorter casting periods. However, it is only economic for high-volume productions

Low-Pressure Die-Casting

Low-pressure die-casting is best for handling metals with low boiling points. It uses vertical chambers that shoot the metal upwards into the die cavity. Castings ranging from 2 to 150 kg are engineered with utmost perfection.

However, the minimum thickness of the casting to be used in this method is 30 mm. so, it isn’t favorable for materials with thin tin walls. On the plus side, it can be easily automated and is inexpensive compared to other die-casting techniques.

Conclusion

In conclusion, choosing a die casting process mainly depends on the concerned project. For instance, the hot chamber die-casting method works well for low melting points metals and bulk productions.

Whereas for metals with high melting points and needing dimensionally accurate castings, the cold chamber die-casting method is best. Furthermore, there are other approaches for various metrics like pressure conditions and automation.